https://www.jst.go.jp/pr/announce/20250409/pdf/20250409.pdf

https://pubs.acs.org/doi/10.1021/acsaenm.5c00084

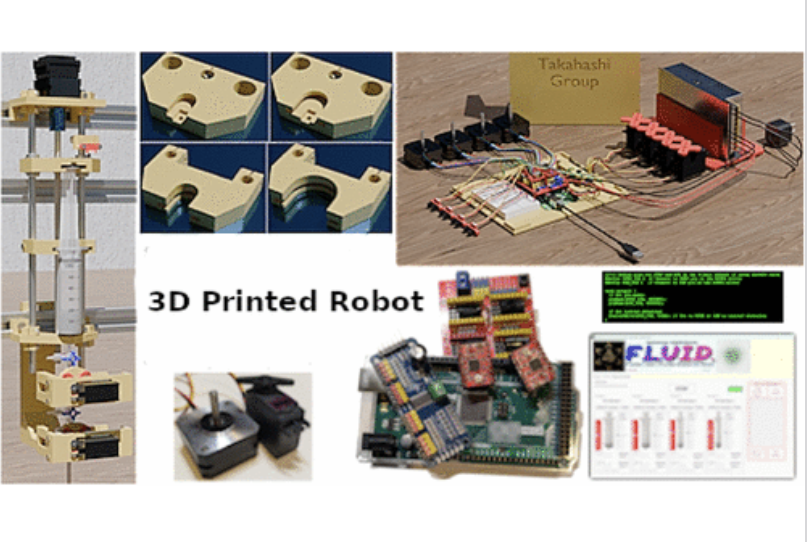

A research group from Hokkaido University has developed a material synthesis robot called “FLUID” that can be fully self-made using a 3D printer.

It that can be constructed only with general-purpose parts that are inexpensive and available to everyone. Most of the parts were printed with a 3D printer and could be assembled without using special parts such as screws and motors. When constructing a robot using only general-purpose parts, precise movement control was a technical challenge, but by developing a unique mechanism design and unique control software, they were able to achieve high-precision operation at low cost.

The biggest feature of this robot is that it is completely open source. All of the design drawings, electrical circuit diagrams, embedded systems, assembly methods, 3D printer design files, source code for the robot control software, and a list of parts used have been made public.

The robot, “FLUID” succeeded in synthesizing nickel and cobalt oxides without human intervention by implementing the coprecipitation method In this study, a unique software enabling solution supply rate and mixing process to be precisely adjusted. This enabled a fluid control that was difficult even with conventional expensive equipment, making it possible to synthesize oxides with uniform particle size and composition.

Free access to anyone is available under the GPL 3.0 license on GitHub (https://github.com/Materials-Informatics-Group).