https://www.nedo.go.jp/news/press/AA5_101827.html

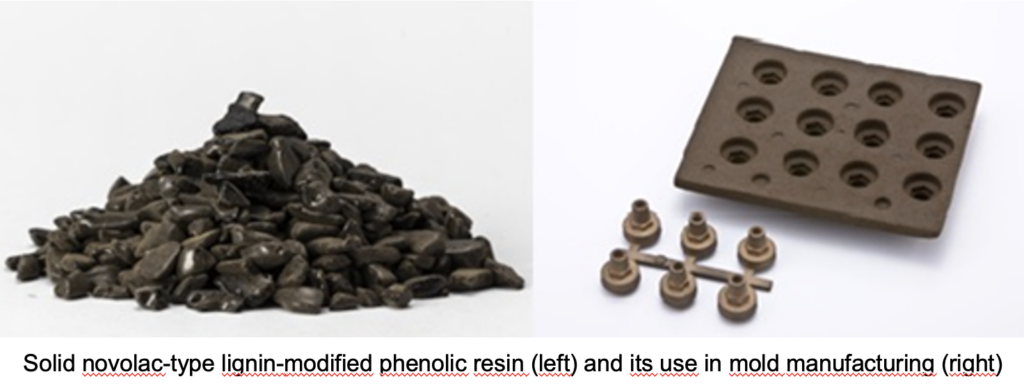

Sumitomo Bakelite Co. has been developing core technologies for resin synthesis using plant-derived raw materials and industrial applications. As a result, the company has succeeded in mass production of “solid novolac type” lignin-modified phenolic resin using lignin and has begun commercial sales for the first time in the world. It has already been adopted as a binder resin for RCS (resin coated sand) for casting, reducing fossil resource usage by 15% compared to existing resins.

Sumitomo Bakelite aims to expand the application of “solid novolac type” lignin-modified phenolic resin to automotive parts and various binders, taking advantage of the mass production and commercialization of the resin.

There have been many research examples of “liquid resol-type lignin-modified phenolic resin” obtained under alkaline catalyst, and social implementation is progressing in adhesives for wood materials. On the other hand, “solid novolac-type” lignin-modified phenolic resin obtained under acid catalyst has not been implemented in society because most lignin is difficult to melt and dissolve. In order to promote early and steady social implementation of lignin, Sumitomo Bakelite has established a mass production system for lignin-modified phenolic resin using “pulp manufacturing process-derived lignin,” a by-product of paper pulp manufacturing and a stable procurement source, as a raw material, and has succeeded in commercializing the world’s first “solid novolac-type” lignin-modified phenolic resin.