https://jp.mitsuichemicals.com/jp/release/2024/2024_0322/index.htm

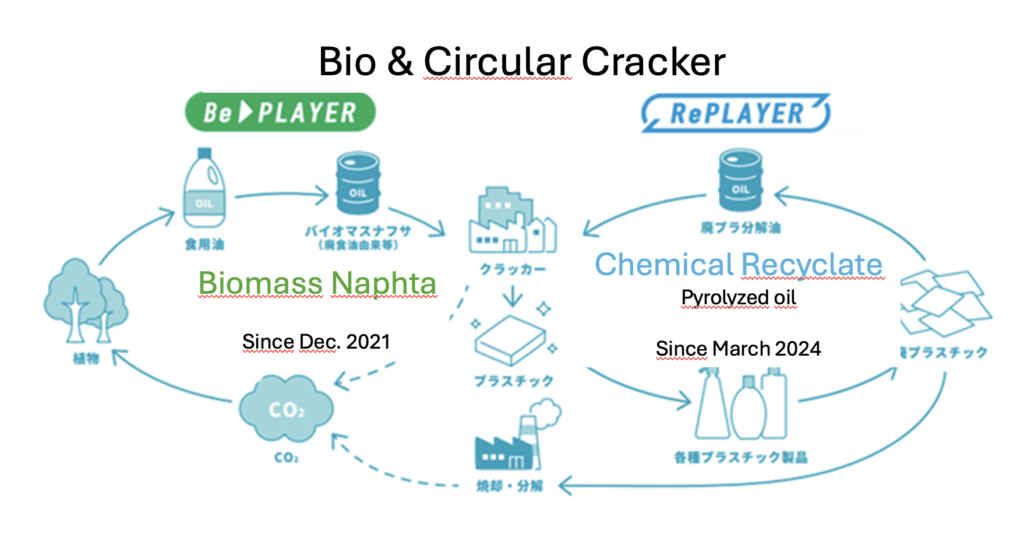

Mitsui Chemicals has started to use pyrolyzed oil (hereinafter referred to as waste plastic decomposed oil) procured from CFP Co. in its cracker at Osaka factory (Takaishi City, Osaka Prefecture) for mass production of a wide range of products (chemicals and plastics). Waste plastic cracked oil (“RePlayer”), like petroleum-derived naphtha and biomass naphtha (“BePlayer”), is a hydrocarbon oil, and by feeding it into a cracker, basic raw materials such as ethylene, propylene, C4 and C5 fractions, and benzene are produced. Since basic chemicals such as phenol and plastics such as polyethylene and polypropylene are manufactured from the obtained basic raw materials, the physical properties of derivative products (chemicals and plastics) are equivalent to existing products (virgin products).

The relative contents of bio and recycled raw materials in these products will be determined using the mass balance method.

In addition, waste plastics produced by Kao Corporation will be used as raw materials in a joint study to implement a circular scheme through chemical recycling to manufacture recycled plastic and use it in Kao products.