https://www.nedo.go.jp/news/press/AA5_101695.html

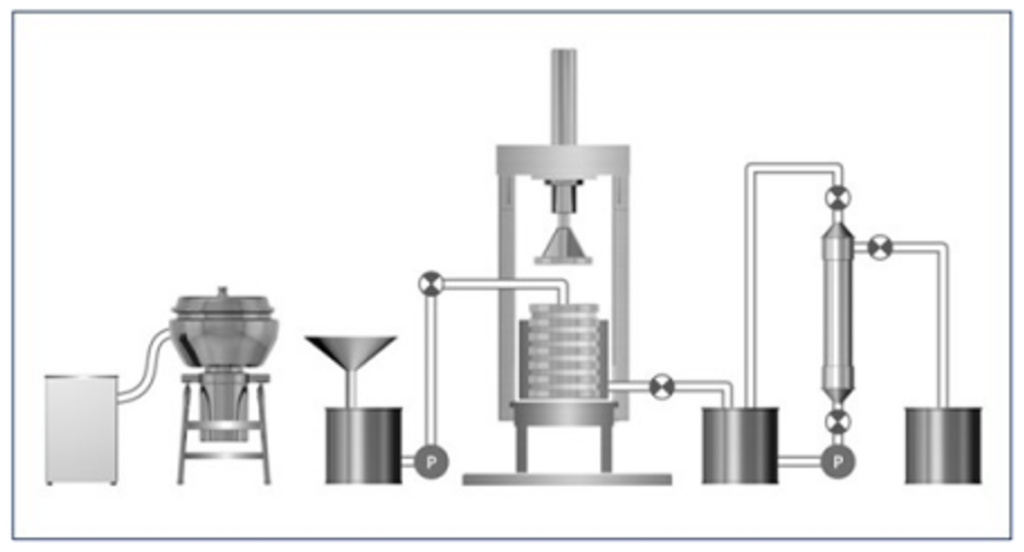

Kajima Corporation is participating in joint research on the “Demonstration and Development of a Large-Scale Production System for Useful Materials Using Genetically Modified Plants” under NEDO’s “Development of Bio-based Product Production Technology to Accelerate the Realization of Carbon Recycling”. As part of this research, Kajima has recently developed an integrated extraction system that can extract target proteins produced in cells by genetically modified plants in a short time and with high efficiency. This system optimizes the three processes from crushing to microfiltration necessary for the production of the target protein, and while achieving high protein extraction efficiency, it can omit many processes conventionally required to remove unwanted plant-derived particles.

(1) Crushing

The crushing processor developed by Kajima is a rotary blade system equipped with a cooling mechanism, which suppresses the temperature rise that occurs during the crushing process. This makes it applicable to the extraction of a variety of proteins with different heat tolerance, and the ability to crush for a long period of time is a feature of the high extraction efficiency. In this process, buffer solution and filtration aids can be mixed at the same time as crushing, thus eliminating the mixing process prior to solid-liquid separation.

(2) Solid-liquid separation/clarification

This process removes as much unwanted solids as possible from the crushing liquid containing the target protein. The solid-liquid separation/clarification process developed by Kashima combines a cold-press solid-liquid separator, which does not require a temperature increase, with an optimal filter aid that does not easily absorb proteins. This allows for solid-liquid separation of large volumes of crushed liquid while maintaining both high clarity and target protein recovery rates. This process reduces the time required for the next stage of microfiltration treatment and reduces the load on the microfiltration filter.

(3) Microfiltration

This process uses a filter with a pore diameter of 0.2 µm to feed the filtrate to the refining process. In addition to removing particles that would interfere with the purification process, it also removes genetically engineered bacteria used in the transgenic process to comply with the Cartagena Act. The microfiltration equipment employed by Kashima features the Tangential Flow Filtration (TFF) method, which is less prone to clogging compared to the general filtration technology (normal flow filtration), in which particles are separated by passing liquid perpendicularly to the filter. The synergistic effect of the clarification process results in a high efficiency of filtrate recovery and eliminates the step-by-step filtration process normally performed.