https://www.nedo.go.jp/news/prehttps://fermelanta.com/ss/AA5_101655.html

There are many rare and useful components in substances extracted from plants and microorganisms, but the production of substances in nature is unstable in supply and costly. In particular, agricultural production methods are a major barrier to industrial production due to the time-consuming cultivation of the plants, as well as the limited cultivation conditions and environment. Although there have been successful examples of mass production using genetically modified plant material and cultured cells, a universal mass production method has not been established. In addition, the production of rare plant-derived ingredients by microorganisms requires the introduction of 10 to 30 types of foreign genes into cells, which is impossible with conventional technology.

Therefore, NEDO (New Energy and Industrial Technology Development Organization) has been promoting a technology development project to artificially maximize the substance production capacity of plant and microbial cells. As part of this project, Ishikawa Prefectural University, a public university corporation, developed technology in 2018 in a joint team led by Kobe University, National Institute of Advanced Industrial Science and Technology (AIST), Chiba University, RIKEN, and others, to create “smart cells” that produce pharmaceuticals, cosmetics, health foods, and high-performance chemicals.

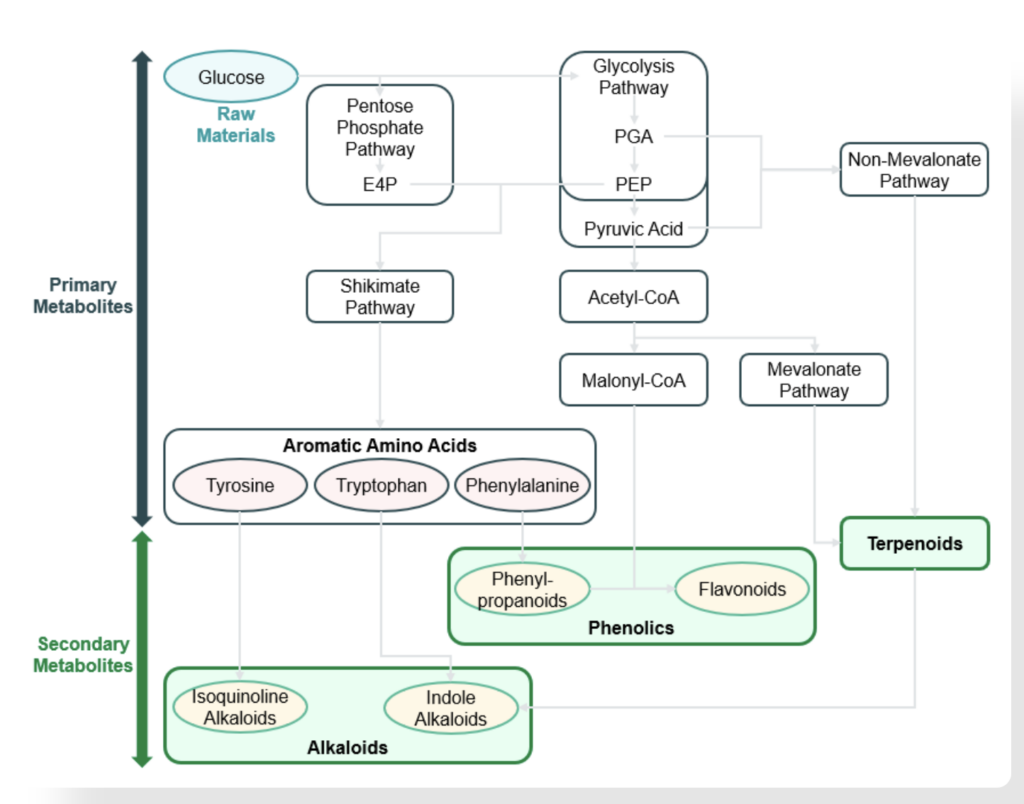

This technology is based on a microbial production process technology that uses synthetic biology to produce plant-derived chemicals in microorganisms in a sustainable, scalable, and inexpensive manner. The researchers succeeded in constructing an efficient modified biosynthetic pathway for plant secondary metabolites in E. coli by combining optimal biosynthetic genes from various species using information analysis technology . At the same time, they established a multi-step gene transfer technology that enabled the introduction and appropriate expression of more than 20 foreign genes into a single organism. With this technology, they have developed a highly efficient microbial fermentation production system for intermediates that serve as a platform for various alkaloid compounds*and pharmaceutical raw materials, using glucose, a commonly used raw material in microbial fermentation production.

By combining this technology with Pharmaranta’s proprietary technologies, more than 20 biosynthetic pathways have been constructed within the cells, and a standard for practical production, i.e., a fermentation rate of 1 gram per liter of culture medium, has been achieved. This enables fermentation and production of more than 1 gram per liter of culture solution, which is the standard for practical production. This yield enables the supply of raw materials for pharmaceuticals and other products at a lower cost than traditional agricultural production methods.