https://bio.nikkeibp.co.jp/atcl/news/p1/23/04/12/10582/

At the JSBBA conference 2023, Kao has announced the production of gallic acid, a raw material for semiconductors and other products, and of 4-amino-3-hydroxybenzoic acid (4,3-AHBA), a raw material for plastics, both from glucose. Corynebacteria are used for production, and a dedicated metabolic pathway has been constructed for each compound.

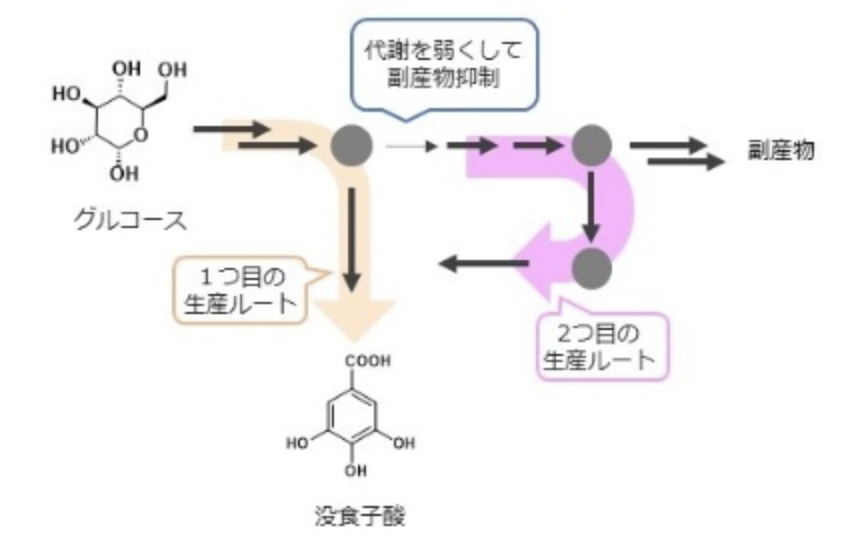

Gallic acid is an aromatic compound extracted from the hump-shaped protuberances, or “insect bumps,” on plants of the poison ivy family, and is in high demand as a semiconductor raw material. The research team has introduced multiple pathways for the synthesis of gallic acid in coryneform bacteria, enabling more efficient biosynthesis than previously possible. The production efficiency of gallic acid was improved by (1) introducing a known synthetic pathway into the coryneform bacteria, and then (2) introducing a second new synthetic pathway in addition to the known pathway. As a result, the yield of gallic acid to raw sugar in mini-jar culture was increased 1.8-fold compared to synthesis using a single known synthetic pathway. However, even at this stage, the efficiency has not yet reached the level of industrial production. While details are not disclosed at this time, Kao is developing other technologies to increase production efficiency in addition to those mentioned above, and will continue to combine these technologies in the future. In the future, Kao aims to sell the product as a raw material for use in the production of gallic acid.

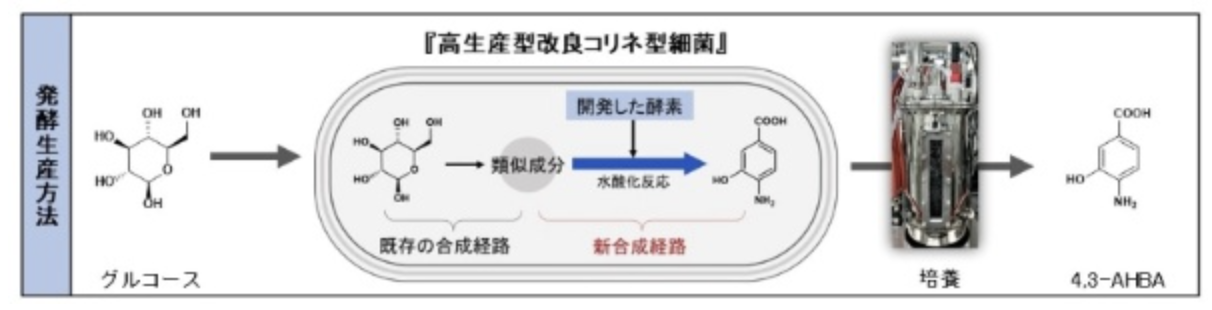

4,3-AHBA is a raw material for plastics, and is a new material for which we will be developing applications. It has high strength and heat resistance, and can be used for protective clothing, tires, and concrete reinforcement. While bioplastics made from plants are becoming more widespread, there are still few examples of the development of materials with high strength and heat resistance, and Kao sees an opportunity to enter the market. With the promotion of electric vehicles, there is a movement to change car body materials from metal to plastic to reduce weight, and Kao expects to see demand in such scenes. Since no production has been done on a practical scale so far and the selling price as a reagent is very high, Kao will seek to utilize it as a material in large-scale production through biosynthesis.

The research team focused on the fact that coryneform bacteria are known to biosynthesize 4-ABA, a component similar to 4,3-AHBA, because it is possible to produce 4,3-AHBA by hydroxylating a portion of 4-ABA. The enzyme that performs this hydroxylation reaction has not been found before and was artificially developed in this research. They identified known enzymes that cause similar reactions, substituted amino acids, and created an enzyme that can efficiently cause the targeted reaction. To screen the enzymes, they employed a high-throughput method that can distinguish 4,3-AHBA production by color.

Since 4,3-AHBA is a new material, it is necessary to develop its application in parallel, and commercialization is expected to take more time than the aforementioned carbolic acid, but Takahashi, group leader of the research team, says, “Research to make microorganisms produce substances by creating biosynthetic pathways that do not exist in the world is currently a goal of ours. However, Group Leader Takahashi of the research team says, “Research to make microorganisms produce substances by creating biosynthetic pathways that do not exist in the world is currently being pursued intensively, and this research is one example of such research. We hope to develop new applications and customers, including through collaboration with other companies.