Osaka University, Shimadzu, and Sigmaxis Collaborate on Automated 3D Printed Cultured Meat Production

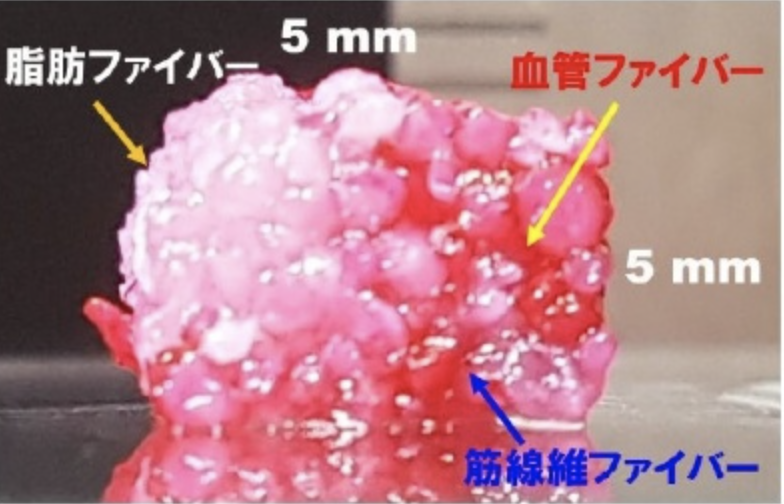

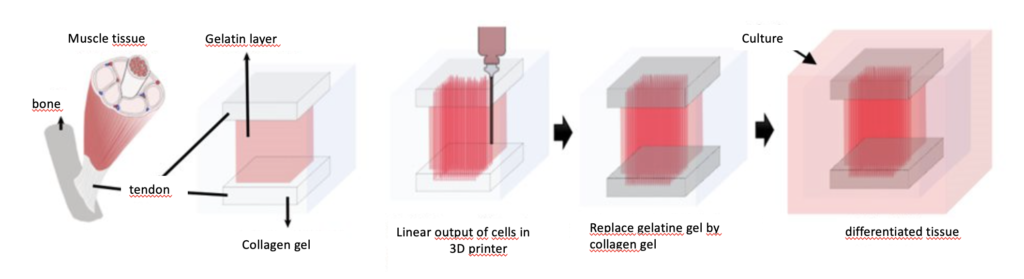

Professor Noriya Matsuzaki of Osaka University, Shimadzu Corporation, and consulting firm Sigmaxis are collaborating to develop automated manufacturing technology for cultured meat using 3D printing. They use Professor Matsuzaki’s technology where myocytes, adipocytes, and vascular endothelial cells are extracted from beef-cells, and after pre-culturing in liquid medium, put through a 3D printer for differentiation and culture. The printer output is a culture tank filled with gelatin and lined with collagen on the bottom and surface layer. Gelatin and collagen have different melting conditions. Only the gelatin is liquefied and removed, allowing the center layer to be replaced by liquid medium. The collagen remains in gel form and acts as a “tendon” to hold the ends of the fibers together to prevent them from contracting and collapsing. Before shipment, the fibers will be bundled into a single bundle and glued together to form the structure of the meat.

Shimadzu has technology for measuring the taste of plant-derived meat, and this technology will be applied to cultured meat. The company uses high-performance liquid chromatography (HPLC) to measure amino acids and other components that lead to umami, gas chromatography (GC) to measure odor, and a texture analyzer to measure elasticity, which corresponds to chewiness. The advantage of this method is that it is less expensive than human sensory testing and the results can be expressed more objectively. In addition to verifying the taste of the meat produced and improving the culture process, the company also plans to market a system for quality checks in the future, along with an automated culture system. Sigmaxis is a future marketing partner.

https://bio.nikkeibp.co.jp/atcl/news/p1/22/04/08/09354/

The University of Tokyo and Nissin Foods Holdings have taken a different approach.

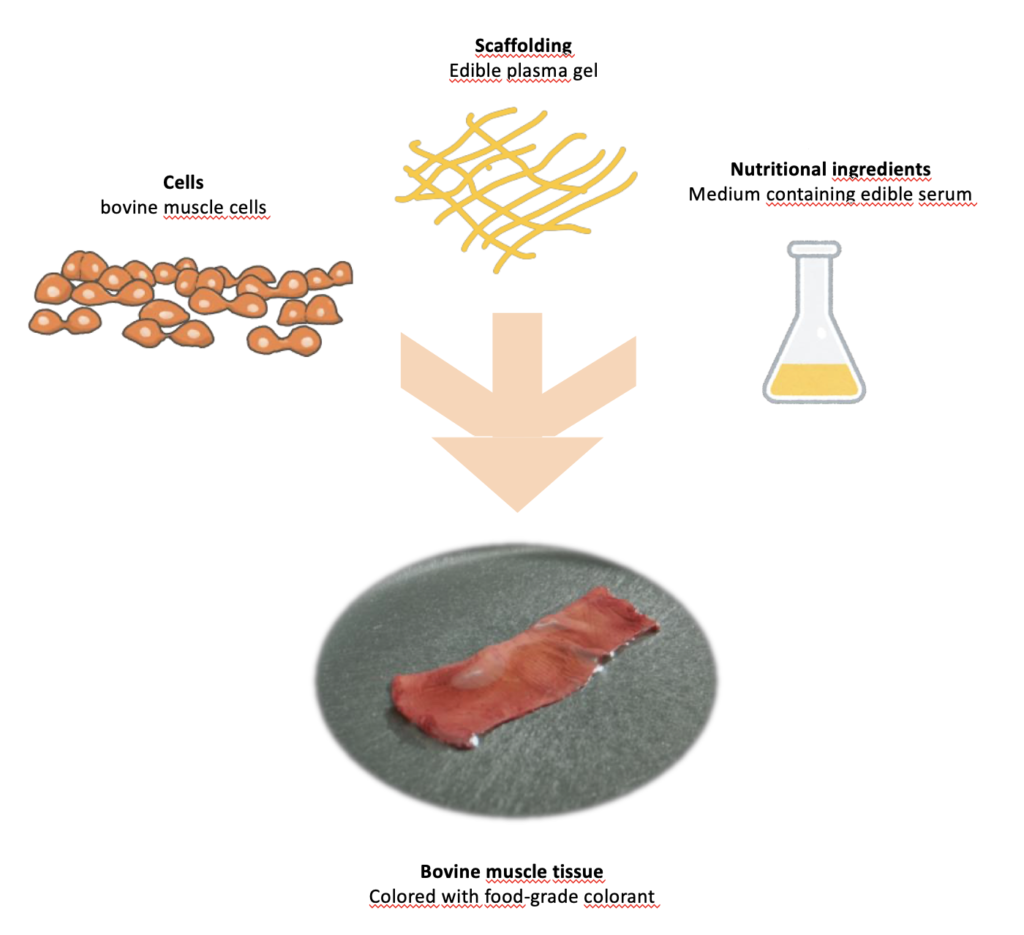

Professor Shoji Takeuchi of the University of Tokyo and Nissin Foods Holdings Co. cooperate on this project since 2017. For cultivation of cells, they use “edible serum” and “edible plasma gel” approved by the University of Tokyo’s Ethics Review Committee and on March 29, a tasting was held for “deliciousness” in terms of taste, aroma, and texture. The “edible serum” contains nutritional ingredient necessary for growing cells. The “edible plasma gel” is a scaffold material for the cells needed to produce three-dimensional muscle tissue (cultured steak meat). The culture is done under aseptic conditions. The size of the steak shown is 2 cm (thickness) x 7 cm (width) x 7 cm (depth)